PIPELINE CLEANING

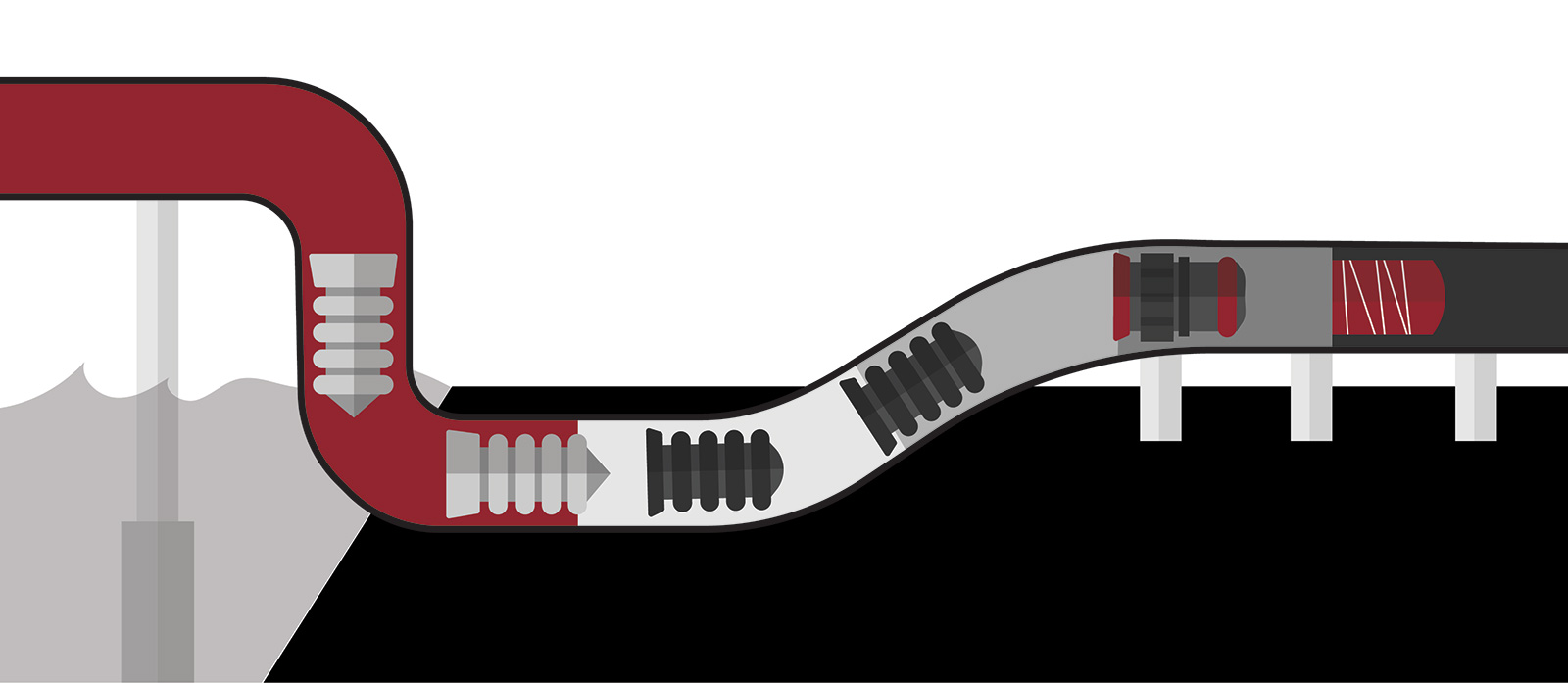

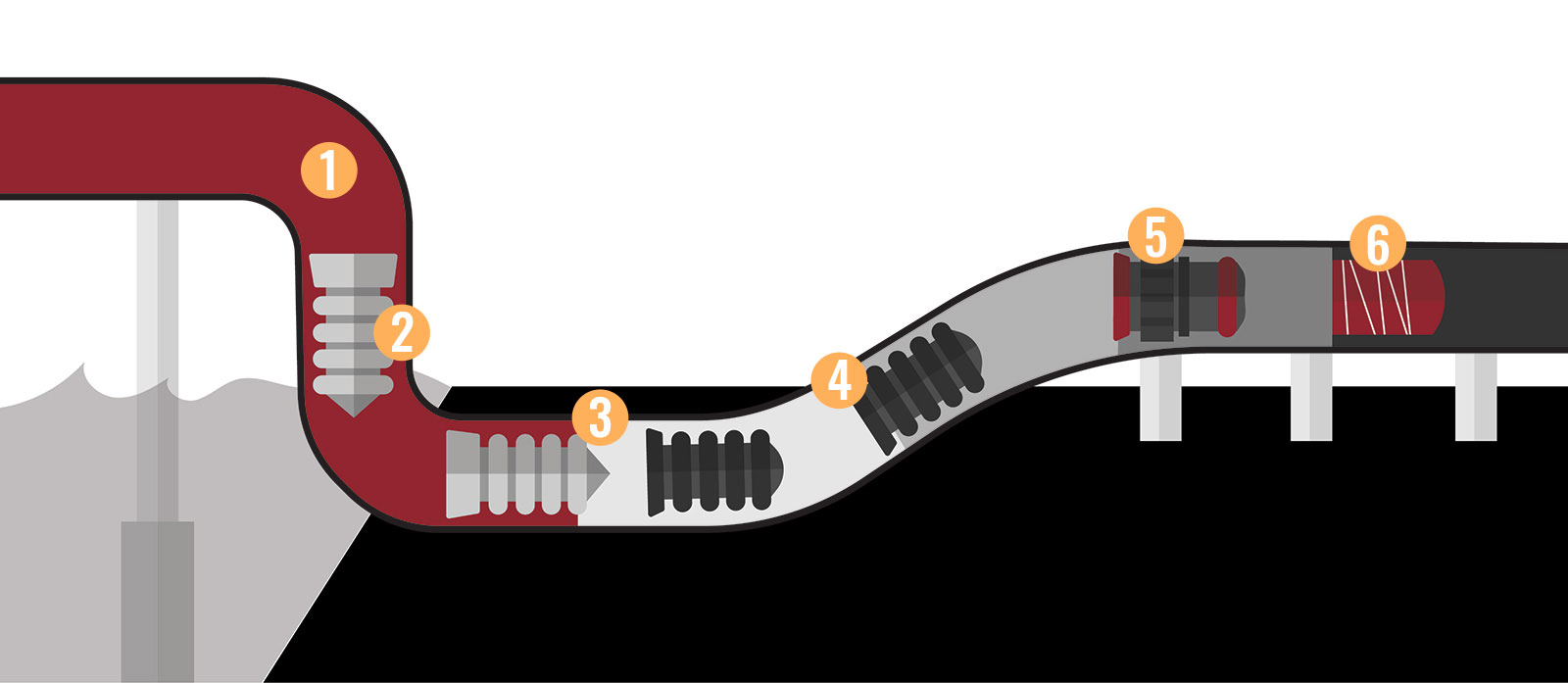

Surface preparation is the most critical factor to ensure the coating will bond properly to the pipe wall. The in-situ coating process involves a combination of mechanical and chemical cleaning. The I.P.S. process has proven its self to be an outstanding method for obtaining the proper surface preparation and is capable of producing a SSPC-SP 5/NACE No. 1 white metal surface.

The I.P.S. process can be utilized for newly installed pipelines as well as rehabilitating existing pipelines

-

Epoxy Coating

-

Coating Pigs

-

Chemical Cleaning

-

Squeegee Pigs

-

Mechanical Cleaning Scraper Pig

-

Mechanical Cleaning Wire Brush Pig

THE IPS DIFFERENCE

CHEMICAL CLEANING

I.P.S. is capable of carrying out a multitude of various pipeline cleaning operations. Specialty operations is our specialty. When it comes to tackling those seemingly impossible projects, then look no further than I.P.S. The top notch personnel at I.P.S. has performed countless pig runs and chemical operations, achieving successful results within difficult & unique situations all around the world.

CHEMICAL CLEANING

I.P.S. is capable of carrying out a multitude of various pipeline cleaning operations. Specialty operations is our specialty. When it comes to tackling those seemingly impossible projects, then look no further than I.P.S. The top notch personnel at I.P.S. has performed countless pig runs and chemical operations, achieving successful results within difficult & unique situations all around the world.

PIPELINE COATING

IPS’ multi-stage In-Situ preparation and coating process has proven to be extremely effective in completely and uniformly covering the entire length of pipeline with a continuous epoxy barrier.

CORE VALUES

Our core values are not just words on a page to us. Our core values are what we believe in and we hold a zero-tolerance policy against anything that comprises our values. If a job can’t be achieved in tandem with our core values, then that job is not worth doing.

PIPELINE REHABILITATION

IPS’ utilizes a multi-stage system that consists of both mechanical and chemical cleaning. Prior to coating, IPS will determine that the proper level of cleanliness has been achieved.

PIPELINE COATING

IPS’ multi-stage In-Situ preparation and coating process has proven to be extremely effective in completely and uniformly covering the entire length of pipeline with a continuous epoxy barrier.

CORE VALUES

Our core values are not just words on a page to us. Our core values are what we believe in and we hold a zero-tolerance policy against anything that comprises our values. If a job can’t be achieved in tandem with our core values, then that job is not worth doing.

PIPELINE REHABILITATION

IPS’ utilizes a multi-stage system that consists of both mechanical and chemical cleaning. Prior to coating, IPS will determine that the proper level of cleanliness has been achieved.

“We consider the highly-skilled team that IPS has built over the years to be the very best in the business and we never hesitate to recommend them for projects.”

Keith RachelEngineering Manager, Sigma Coatings USA